Specializing in Vacuum & Dip Brazing for Aerospace/Defense and Critical Industrial Sectors

Custom Solutions

- Streamlined processes, tailored to your specific requirements – from design to delivery.

- State-of-the-art vacuum furnaces

Quality Assurance

- Certified to AS9100

- Compliance to AWS C3.7 and AMS 2700

Core Services

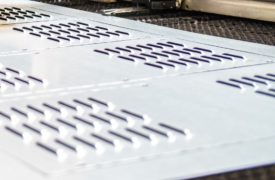

Aluminum Vacuum Brazing

- Joining metals with minimal oxidation.

- Can be performed on metal objects with differing dimensions.

- Ideal for high-level thermal performance applications, requiring strict consistency.

Aluminum Dip Brazing

- Cost-effective, efficient method for joining aluminum components, by flowing a filler metal between the joint interfaces.

- Precise control over the process for consistent, reliable outcomes

- Perfect for complex 3-D geometries like chassis, housings, & waveguides

Value-Added Services

Design and Engineering

- From concept to final design, expert engineers bring your concept to life

- Utilization of latest CAD & simulation tools for brazing optimization

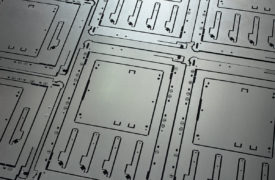

Prototyping and Production

- From prototyping to full-scale production

5 Amada CNC Laser & Turret Machines

* Lasers: 4,000 Watt

* Turrets: 58-station 4 A/I turret

* Turret speeds to 1800 hits per minute

* Sheet capacity sizes up to 60” x 120”

* Integrated and automated material handling load/unload systems

* Computer networked & built-in redundancies

* Multiple machines capable of processing same parts

* “Lights Out” fabricating capability – Remote video monitoring

EML-K 3610 4KW

Laser/Punch Combo

58 Station, 4 A/I – 1800 Hits Per Minute

Capacity: 60″ X 120″ Max Sheet Size

M5-F750 Nitrogen Generator – 30 HP

VSD 3-Shelf RMP 510 – TK Parts Picker

Integrated Load/Unload – Material Storage Capacity: 16,000 lbs

3D Forming at Punching Stage

“Lights Out” Capability

FOMII 3015NT 4KW Laser

Max Thickness: Steel: 1-INCH – SS: 5/8-inch – Aluminum: 1/2-inch

Capacity: 60″ X 120″ Max Sheet Size

Repeatability +/- 0.0002″

M5-F1500 Nitrogen Generator – 60 HP

VSD ASLUL 8-Shelf Integrated Load/Unload – Mat’l Storage Capacity: 50,000 lbs

“Lights Out” Capability

Vipros 358K

58 Station, 4 A/I – 700 Hits Per Minute

Capacity: 50” X 120” Max Sheet Size

04PC Control

6 Shelf ASR 410 Integrated Load/Unload – Material Storage Capacity: 28,000 lbs

“Lights Out” Capability

Vipros 358K

58 Station, 4 A/I – 700 Hits Per Minute

Capacity: 50” X 120” Max Sheet Size

18P Control

2 Shelf MP 1530 Integrated Load/Unload – Material Storage Capacity: 10,000 lbs

“Lights Out” Capability

Pega 345

58 Station, A/I – 300 Hits Per Minute

6M Control Stand Alone/MP Ready

Tooling

~ Extensive Tooling Library

~ Togu Manual Tool Grinder

~ Togu III Automatic Tool Grinder

~ NCT3 Turret Tapping Tools

Material Thickness

Lasers & Turret Punches: 0.012 to 1 inch

Material Type

Common Material Types: Aluminum, Hot & Cold Roll Steel, Stainless Steel, Galvanized & Galvannealed Steel, Copper, Brass, Inconel, Plated Material, Pre-Painted Material, Lexan

Software

Solidworks, SMP Merry Mechanization, Nestmaster Nesting Software, Amada Dr. Abe Blank & Dr. Abe Bend, Amada Sheet Works